Tubular Level Gauge

Product Details:

Product Description

Tubular Level Gauge

To meet the precise requirements of our clients, we manufacture, export and supply Tubular Level Gauge. The offered gauge is manufactured and developed using quality approved raw materials and the latest techniques under the supervision of our adept professionals. Our level gauge is used in various industries for measuring the liquid level and automatically closes the valve seat to prevent wastage of the fluid. Also, our offered Tubular Level Gauge is made available with us to our clients in various technical specifications at marginal prices.

Key Features:

- Elevated durability

- Simple to fit

- Dimensional accuracy

- Long service life

- 360o Visibility with tie-rod guards.

- Glass removal/replacement possible w/o dismantling of gauge.

- Offset isolating valves permit cleaning of glass gauge w/o removal.

Construction & Operation:

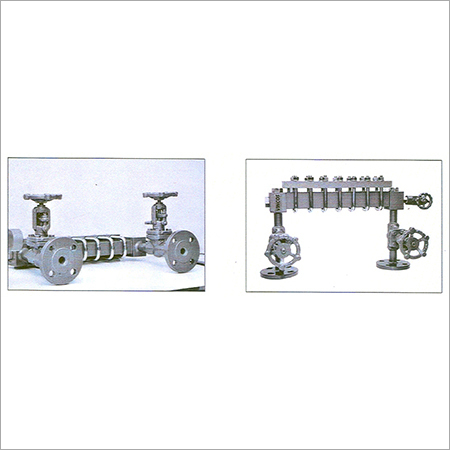

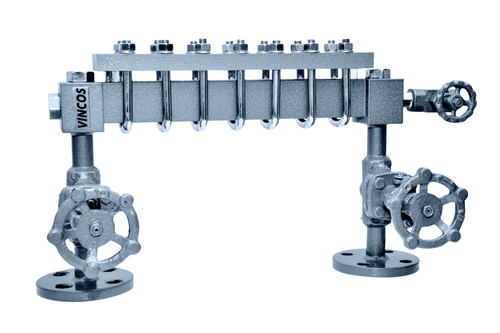

Gauge is fitted between two end blocks though gland packing's. The gauge is mounted parallel to tank so as to form a close loop causing tank liquid to seek its level in the gauge. Guards are provided in the form of tie-rods/c-channels around the gauge to protect it from accidental blows. End blocks have built-in isolating valve, drain valve & vent plug.

Special Feature (Optional)

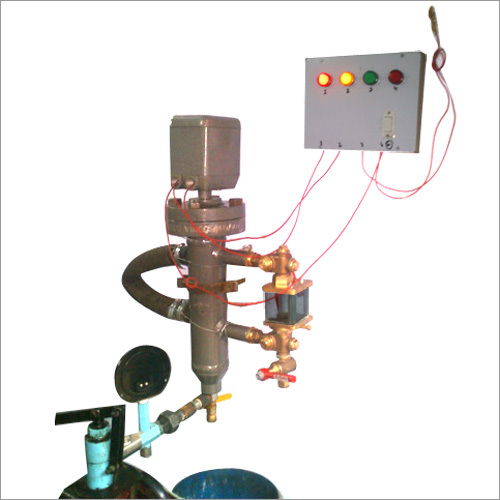

Illuminator: Illuminates poorly lit areas for proper visual indication.

Frost Free: Prevents frost formation on outer surface of gauge glass for clear visual reading in case of liquids at low temperature.

Jacketing: for heating /cooling of process liquid to prevent its solidification

Glass Protectors: To provide additional protection and personnel safety.

Auto Ball Check: Built into end block for preventing liquid loss, during glass breakage.

Standard Specifications:

Gauge: HW Borosilicate Glass 16/25mm OD (25mm for Viscous Liquids)

End Block MOC: CS/ SS 304/ SS 316/ Bronze/ Gun Metal

End Block Type: W/o Valve/Offset NV with or W/o Auto Ball Check.

Guards: CS/SS 304/FRP C-Channels or Tie-Rods

Gland MOC: CI/SS 316

Process Conn: Flanged (ANSI 150#) or BSP Screwed.

Vent/Drain: Plug/Ball valve.

CC Dist. : 3000mm in Single Length, Large CCD though Coupler

Visibility: CC Dist-150mm

Maximum Temp: 200oC(PP)

Test Pressure: 10Kg/cm2